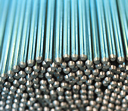

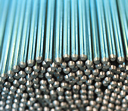

Featuring equipment that is replete in terms of both quality and quantity, our Wadayama plant can flexibly and speedily reconfigure its production lines to deal with the orders at hand to support "small-lot" production setups. In addition, it is possible to put together setups for accommodating "multiple sizes" where the wires have many different diameters by making full use of the wide range of machines in place.

In addition to its vacuum furnaces, the plant has heat treatment equipment capable of supporting just about any annealing system. Many secondary processing manufacturers subcontract the annealing processes after wire drawing and then have the products returned for pickling, but we have our own vacuum furnaces so we can do the annealing ourselves and are able to skip the pickling process.

It is because we have a production environment that is preeminent in the industry and that enables us to complete all the processes ourselves that we can deliver our products in the shortest possible time while maintaining high levels of quality.

One reason why we can offer products in many sizes in small lots and deliver them in the fastest way possible is our extensive inventory of materials. We handle all the kinds of steel stipulated by the JIS G4309, JIS G4318 and other standards, and more than 30 types of general-purpose steel are always on hand at our Wadayama plant.

In addition to the general-purpose steels, we have at our disposal various high-alloy steels, high-carbon chromium bearing steels, heat-resistant steels, steel for forging and steel for springs.

Our stock of plentiful materials and our flexible manufacturing setup join hands to supply products with a high degree of customer satisfaction.